The history of Centerport Cycles is also the story of my tenure in the bicycle industry and my involvement in the sport.

Like many members of the bike industry today I am a product of the “bike boom” of the 1970s. I grew up in Farmingdale, Long Island, N.Y. Both my parents taught at the college there. In 1970 I was 15 and I bought a green Dunelt 10 speed from an auto parts store in Amityville. A year later I sold that bike and upgraded to a white Peugeot UO8. I rode my first century (100 miles), with my (still) pal Wayne Lundstrom, to Montauk Point on the Fourth of July, 1971. I carried a canvas tent, sleeping bag and a fishing rod strapped to my trusty Pletcher carrier.

The following Spring I got a job assembling bicycles at All-Brands Bikes & Luggage in Wantagh. I was one of an army of guys who were putting together Schwinn Varsities and Raleigh Records as fast as humanly possible. There was a top of the line Raleigh Professional hanging on the wall. It was the apple of my eye. A few guys who worked there were pretty cool. They told me where the really hip shops were; Visentin Bike and Mower in Oyster Bay, Vito’s barber shop in Westbury and Engelbosch Cycles in Massapequa. Vito Perucci was a barber who also fixed bikes. He had a racing club, the Nassau Wheelman, and he promoted races. The first time I visited his shop he told me that he was putting on a big criterium in downtown Westbury. I went and watched that race and I was hooked.

Not long after that I stumbled onto a great deal on a used Frejus. It was really beat up but it was a top quality bike, built from Reynolds 531 tubing and equipped with Campagnolo Record components. I had to straighten the fork. I gave it a paint job, repacked the bearings, new cables and handlebar tape, and I was riding in style.

The first time I walked into Engelbosch cycles I wasn’t very impressed. The place was dark and dingy and there wasn’t much inventory. In fact there were no high end racing bikes anywhere to be seen. The old guy behind the counter asked if I needed any help. I said that I was interested in racing. He told me to go in the back and talk to Mitch.

Mitch was a skinny kid, a year younger then me, who was patching a flat tire. We chatted for a while. I told him that I wanted to start racing. He said that he did too and asked if I had a license application. He had just gotten one for himself and he happened to grab an extra. We got our licenses and started training together.

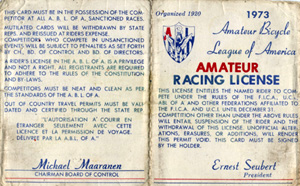

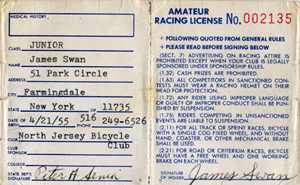

My first racing license. The ABLA predated the USCF. Then ABLA

president Ernie Seubert, who’s name appears on the front of the

licence, is now my agent for frame building insurance. Small world.

My tenure at Brands didn’t last long. I hung around Engelbosch so much that they put me to work. The shop was owned by Joe Sulc. Joe’s uncle, Felix Engelbosh, who started the shop, had emigrated from Belgium where he had been a professional bike racer. I never met the “old man”. In fact he passed away during the time that I was employed there.

Joe’s sister Annie and his son Charles both worked in the shop. Charles was a math teacher at a local school. He worked in the shop after school and on Saturdays. Anne followed the European tradition of the woman handling the wheel building. She treated us like we were her own kids. She fed us and if it was raining, she gave us a ride home. Mitch and I would usually train after school and then go to work at the shop. Joe was pretty cranky, but once you got to know him he was a great guy. He was a good mechanic and he was very generous to us. Engelbosch Cycles had a cozy, old-world feel to it.

Joe didn’t sell too many real racing bikes. He was pretty fed up with the racing crowd and preferred to sell generic “10 speeds” and do repairs. Still there was a strong racing history there. Joe’s kids had grown up racing bikes and speed skating. In fact Joe was an official and a promoter for speed skating. Speed skating is a sister sport to bike racing. I picked up a pair of skates and started fooling around with that as well.

This the only picture that I have of Joe Sulc. He is the guy wearing glasses

right above the red jacket. Joe was officiating the short track races at the

first Empire State Winter Games in 1981 at Lake Placid.

In the ’50s and ’60s Felix Engelbosch had imported Dossche Sport bikes from Belgium. He also did some frame building. There were several half built frames hanging from the ceiling, and boxes of Nervex lugs and Reynolds tubes in drawers. There was quite a bit of vintage racing equipment lying around. Old timers still came in to buy tires or have their bikes serviced. It was fun to hear the stories of the old days.

Engelbosch was a Schwinn and Raleigh dealer. Joe had some kind of partnership with Vic Fraysee over in New Jersey. Vic and his son Mike had a shop and they imported bikes from France under the name Paris Sport. We sold a lot of those bikes. The Fraysees sponsored the North Jersey Bicycle Club so Joe wanted us to ride with them. We signed up, and one day Joe came back from Mike’s with a big box of goodies. We both got a team jersey and shorts (wool of course), leather cycling shoes and helmet, gloves and a pair of tubular tires. All of this stuff was free. We felt like pros! I sold my Frejus and bought a new top of the line Falcon.

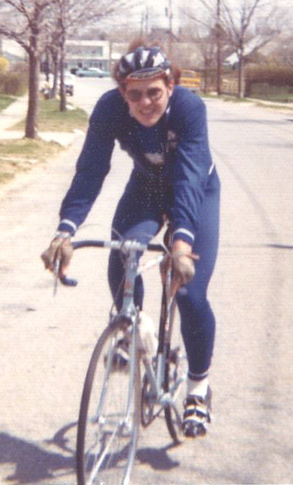

Me in 1973 on my brand new Falcon San Remo 76. Check out

the double toe straps. I fancied myself a sprinter. Also note the

Falcon cap. I think it came in the box with the bike.

Vito started a training race series at the State University at Old Westbury. Those were the first races that we did. I actually won the first one. They had an A and a B category. The B was for Juniors (which we were), Veterans and Woman. Vito let the A group go first and then started the B’s. Mitch wound up getting a cramp and had to stop. Towards the end of the race we got lapped by the A’s and the two groups stayed together. We had one lap to go but the A’s had to go around a few more times. Vito didn’t realize that the groups were together so he didn’t ring the bell for the B group to tell us that it was our last lap.

The finish was an uphill sprint. I’m not sure if I knew that it was the end of the race for the B riders but Mitch was on the side of the road at the bottom of the hill screaming at me to sprint. Somehow I got my wheel across the line first.

We started to travel to open races where the fields were much more competitive. Mostly we got dropped. It took a while before we were strong enough to finish with the pack. It was hard and it was going to get harder. The next year I was going to be 18 and I would have to start riding with Seniors.

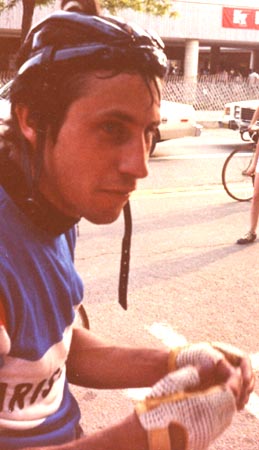

This is a picture of my good friend and training partner “Mitch” taken in the late ’70s.

His real name is Richard Minchik but everybody called him Mitch back then…

We learned a lot of good bike lore at Engelbosch. Annie taught me how to build wheels and I took over that job. Joe taught us stuff like wearing two pairs thin socks in winter with a plastic bag in between. He told us to put a cabbage leaf under our cycling cap on hot days and to put a sheet of newspaper under the front of our jersey on cool windy days. We did the socks and the newspaper thing but I can’t recall either of us using a cabbage leaf. Maybe I should try it.

I graduated from high school a half year early in January ‘73. I had planned to go to college at Oswego and become an Industrial Arts teacher but I was bitten by the bike bug. There really wasn’t enough work at Engelbosch for me to work full time so I started looking around for a serious gig. One of my friends was working at Hempstead Cycles and I got a job there.

This is the only picture that I have of Hempstead Cycles. It shows the back

lawnmower repair shed on the day that the whole place was demolished.

That shop was owned by George Oslander. He was I nice guy and we got along well. The shop had been started by George’s father, Sam, in the ’20s. Sam and his wife Molly lived in Florida but they came up each summer to work at the shop. Sam and I started out as arch enemies but slowly became good pals.

Hempstead Cycles was a big shop with lots of high school and college kids working as mechanics. I was a “lead man” because I had some experience. The money was good and I had a VW bus to go to the races in. They had welding torches there and I learned how to do frame repairs. Come to think of it, I own those torches today.

Check out my VW micro-bus double cab pick-up.

They are pretty rare. I wish I still had it.

I graduated to the Senoir (18 to 35 year olds) ranks in racing. I bought a beautiful Jack Taylor track bike. Mitch and I worked out at the velodrome in Kissena Park but we were too timid to try racing there. One time I was going pretty fast and I forgot to keep pedaling. I had my hands off the bars and went down hard. I got a mile of road rash.

I did a lot of wheel building at Hempstead Cycles. If a bike had a bad rim we didn’t replace the whole wheel, we laced up a new rim. We also built wheels that we sold to other shops and distributors. When business was slow in the winter, George had all the mechanics build wheels. Demand for our wheels became so great that we started to have production wheel building going on around the calendar. I did enough piecework building wheels on the side that I often doubled my paycheck.

I worked there for two years and then decided to go to college. In the Fall of ’75 I went to the State University at Farmingdale where my parents taught. They had a two-year program for mechanical engineering technology that combined engineering with machine shop practice. I had an idea that I wanted to be a tool designer. I really liked the program and I did well. I graduated in ’77.

While I was in school I continued to build wheels for George. I also built wheels for Joe at Engelbosch. On top of that I was building wheels for lots of the guys that I knew from racing. My van was always full of wheels.

One day during my last semester George called me up and asked me to meet him for lunch; he had a proposition. Demand for his wheels was getting out of hand. He was being solicited by many of the big distributors to build wheels for them on a contract basis. He had bought two wheel-lacing machines from a bicycle factory that had recently gone out of business in Brooklyn. The machines where dismantled and he didn’t know if they even worked. I guess the price was right.

George wanted to set up a separate wheel building business with me working as a subcontractor. I had always gotten along well with him so I went for it. I got the lacing machines up and running. We hired a couple of people who had been wheel lacers at the defunct bike factory. I was challenged to use my newly acquired knowledge of manufacturing to set up a mini production line.

The hardest part of wheel building is tightening up all the spokes so that the wheel is concentric and true and the spoke tensions are uniform. It takes a long time to do this by hand. Before we started this enterprise I had been working on methods to make this step faster. Now I had to get serious. I developed a method of using a series of electric drills to tighten the spokes. I bought a metal lathe so that I could make special spoke nipple drivers and other tools.

We had two people who spoked the hubs and laced the wheels; and then it was my job to tighten the spokes and be sure that the wheels were true. It all worked pretty well. I got to the point where I could tension and true 300 wheels a day.

By the time I graduated from college I was making a lot more money then entry-level tool designers so I stuck with the wheel building. It was a great job. I didn’t have to work every day. I was able to do my part of the process much faster then the lacing step so I would only go to work when they had a big pile of wheels laced up. After the first year I hired my friend Jeff Dahlman to help me out. Together we could tension and true 500 wheels a day.